The Homegrown Street: Making of Afzar Ali’s House

The Homegrown Street: Making of Afzar Ali’s House

The Homegrown Street project has reached the phase where the physical models of all the houses are to be made. The first physical model to be made for the Homegrown Street project began with discussions regarding Afzar Ali’s house in Sangam Gully, Dharavi. It was a G+3 structure designed by Giriraj, a contractor from Dharavi.

The process started with multiple, elaborate conversations with a master artisan in wood, Manoj, and the contractor, Giriraj. Since this was the first time making a composite model in steel and wood, these design discussions helped us find clarity.

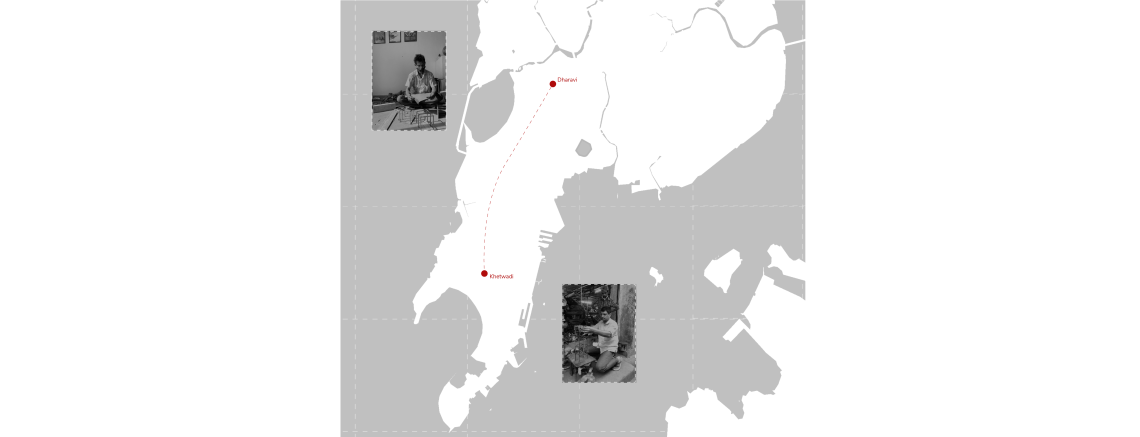

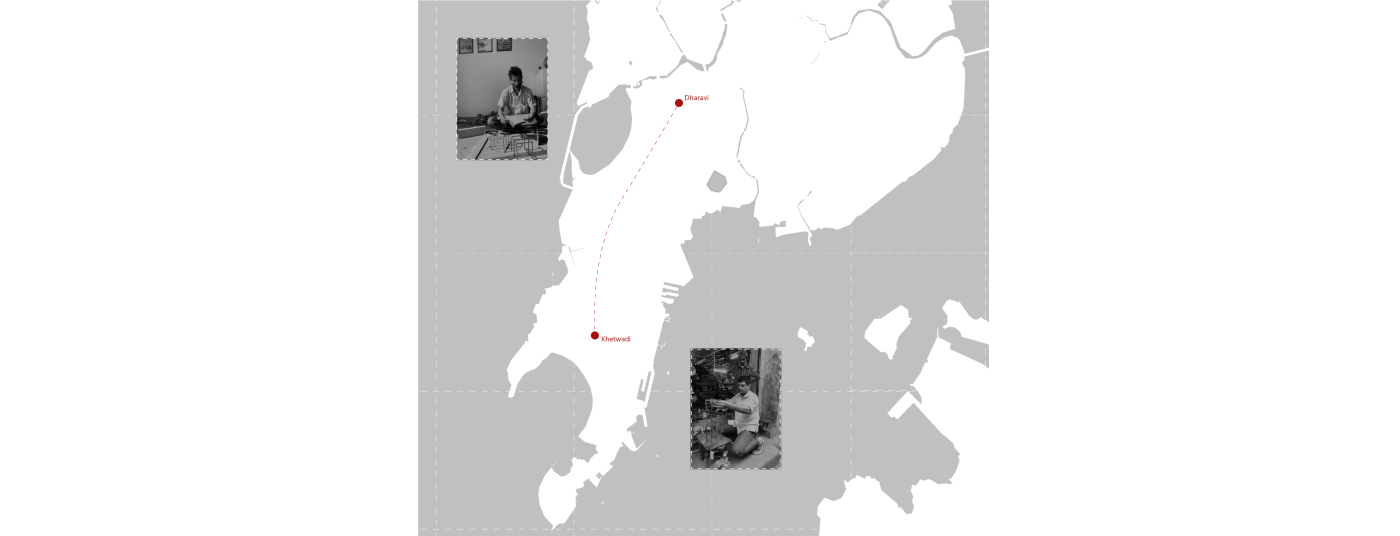

Having previously experienced the work by steel artisans in Khetwadi, it was decided to get the steel frame built by artisans from that area, while the woodworking would be done by Manoj in the Urbz office in Dharavi.

Working in Dharavi and Khetwadi at the same time was the biggest challenge. Collaborating and coordinating while being at two places at the same time was tricky.

Metal pieces were to be welded before any of the woodworking began. However, several small changes constantly needed to be made due to material constraints.

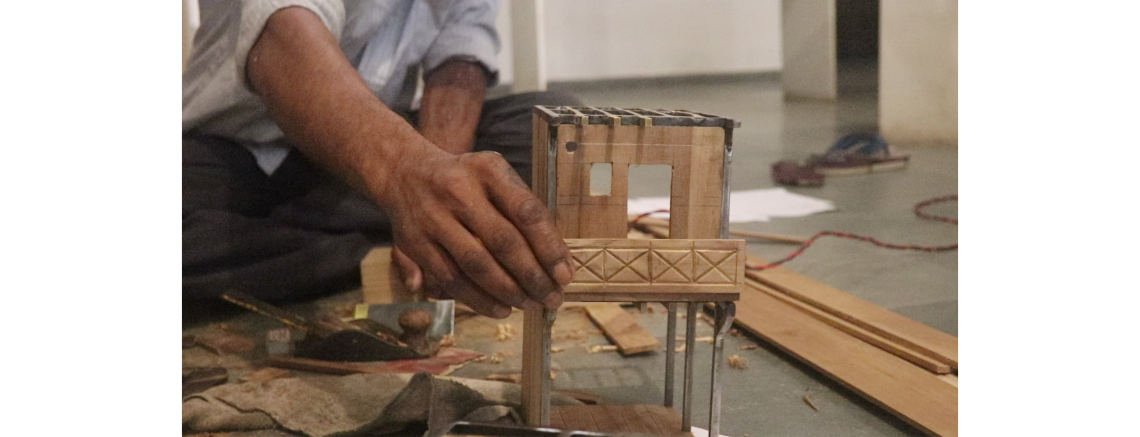

It was essential to keep in mind how all the different aspects of the model were to come together before beginning any part of the production. The columns of each floor had to be threaded before they were welded so that the wooden slab could be screwed tight onto the column.

While the team in Khetwadi got the beams welded onto the frame using brass, the rest were in the office assisting Manoj as he cut and treated the wooden pieces needed for the slabs and walls.

There were a few unforeseen hurdles that came along the way. The process required a lot of back and forth between all the parties involved. Some of the challenges faced during the initial production of the model were changes in material size and type, small measurements, and most importantly making sure that both the artisans were on the same page. It was a challenge to get all parties to agree to key material decisions.

After all the material decisions were made Manoj started fixing the walls and he showed his skills by adding small details.

The making of this model is well underway and has been a source of a lot of learning. This is the first composite model made in two different parts of the city at the same time, and it has come with many challenges. The next stage of the model will be to cut and fit the walls, slabs and the ornamental elements of the model, to complete it. Stay tuned.