Social and Economic Resilience in Dharavi

Social and Economic Resilience in Dharavi

Dharavi embodies an efficient pre-industrial live-work paradigm. This is now desired and interpreted in post-industrial societies, and more so in the Covid-19 era, as a sustainable lifestyle. In Dharavi, the workplace, street, and home are an essential source of building social capital as it creates a conducive environment for skill exchange, mutual support, apprenticeship, and social interaction with family, co-workers, and community, which strengthens social bonds and networks, and still keeps the informal economy thriving. With around 85 communities and 700,000 inhabitants, people from all parts of India - Gujarat, Tamil Nadu, Bihar, Rajasthan, Maharashtra, etc. migrate to Dharavi in search of employment, trade, and a better life. They work together in more than 5000 small and medium scale businesses contributing to over US$1 billion per year to the overall economy. The products produced by these Dharavi SME’s are then shipped to global markets and clients as far as New York, Paris, and the Middle East.

With steep economic growth in the last two decades, Dharavi continues to grow as a hyper-dense settlement, where most people run a business out of their homes, transformed into the workspace on the ground floor while staying on the upper floors. Though there is a severe shortage of space, Dharavi still continues to absorb more people into the economy than other industrial economies which focus on limited workforce and mechanization. Dharavi is home to people with diverse history, ethnicity, lifestyle, and culture as it pools in different skills, crafts, networks, and modes of life which contribute impactfully to the economic paradigm and social capital. Every working community is a complex environment, where every individual node is dependent on all the others, reflecting a compact web of social and economic networks.

In the 18th century, inhabited by the fisherman community called Kolis, Dharavi was a small island. By the late 18th century people migrated in huge numbers to work in its thriving cotton industries and port trade in Mumbai. Eventually, tanneries, potteries, garment makers, and recycling facilities sprung up within Dharavi even without the support of government infrastructure and resources. This 'homegrown' marginalized neighborhood in the heart of Mumbai houses thousands of artisans, craftspersons, and mechanics, working in workshops and factories which are often doubled up as homes and dormitories. The establishment and growth of Dharavi can be attributed to economic opportunities created by the highly engaged people of these communities. They generally come from the same geographic region or social background through a support network of acquaintances in Dharavi and are able to learn skills over time that make them economically stable.

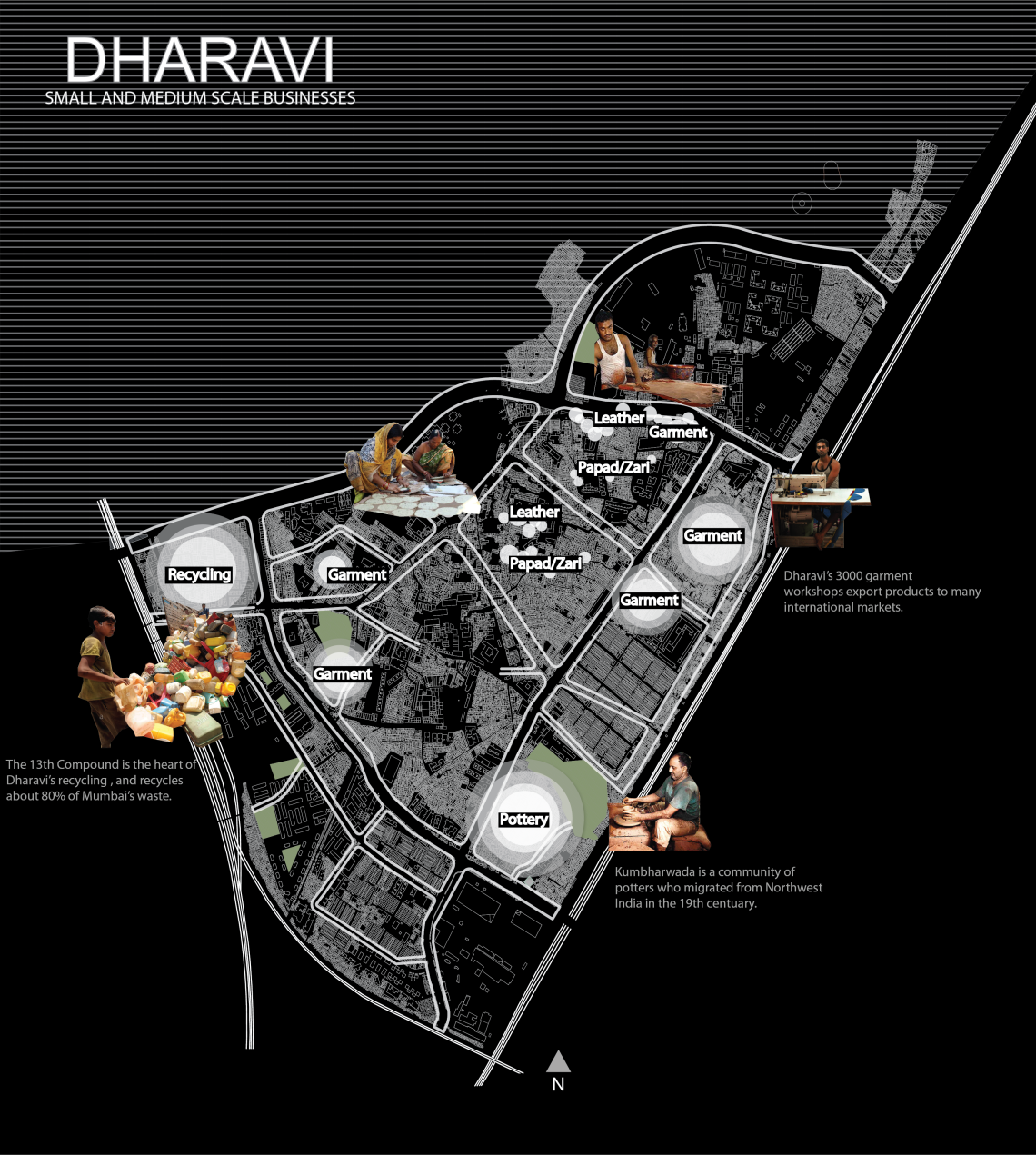

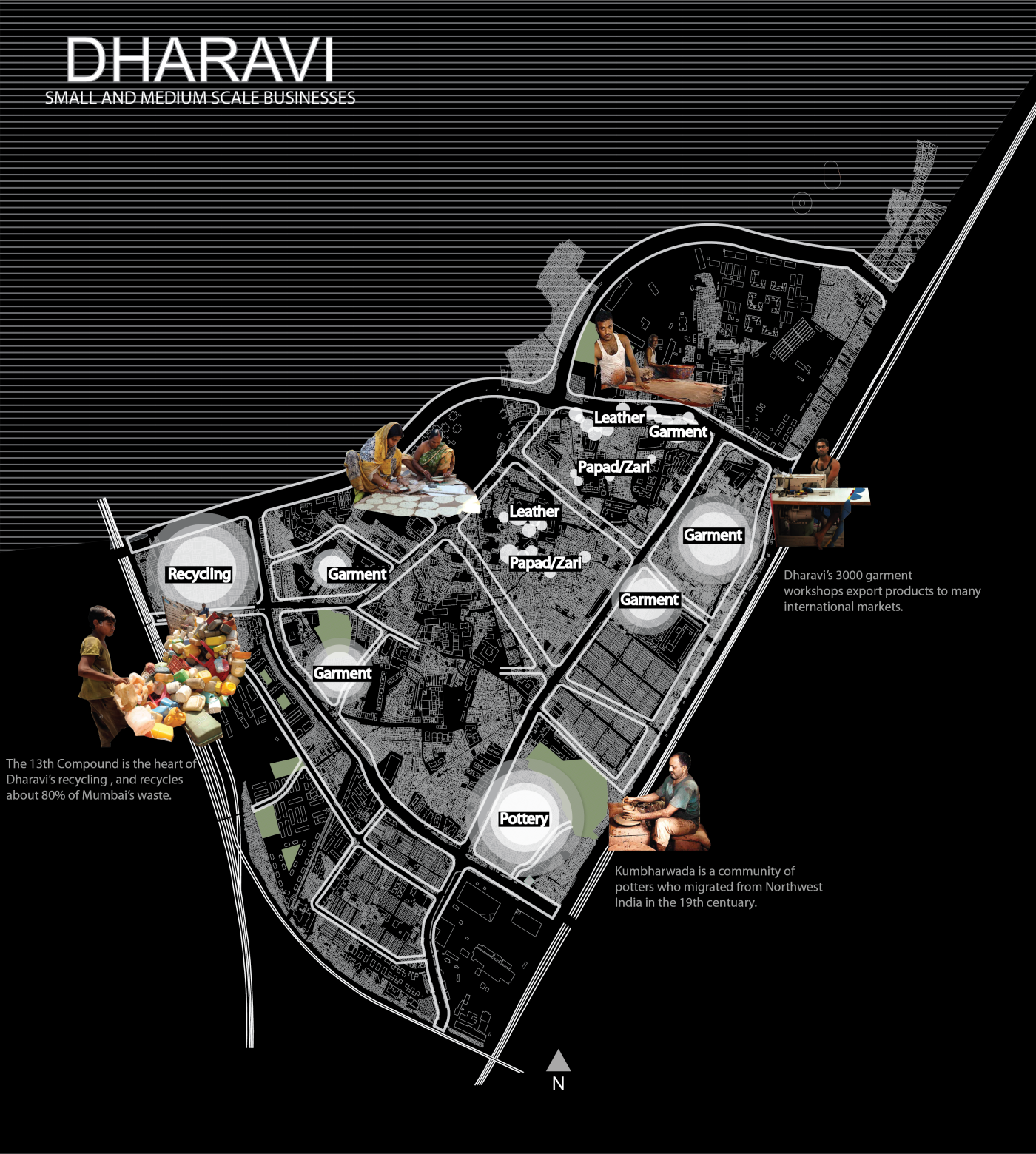

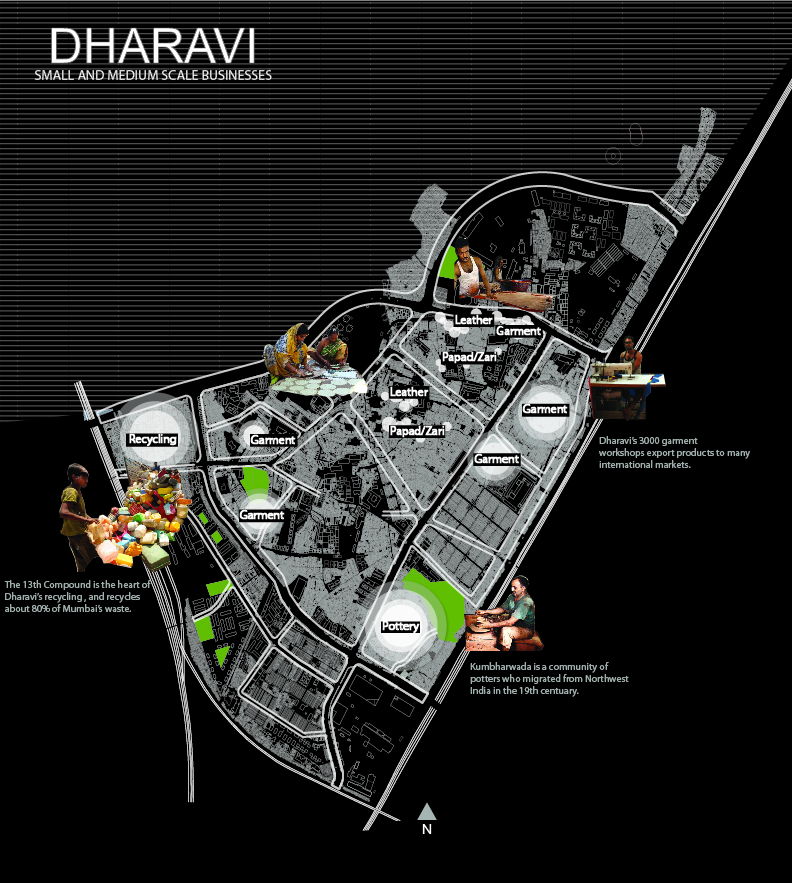

Different types of small to medium scale businesses such as the Pottery industry in Kumbharwada, the Recycling industry at the 13th compound, Garment industry in Bareilly compound, Leather Industry along the 90-feet road, and many more in Dharavi have developed over 100 years ago and passed onto generations. As the city grew, Dharavi became a bustling central location to famous local crafts and craftsmen from all over the country who brought their family trade with them and expanded their businesses.

One of the earliest settlements at Kumbharwada houses the pottery community. The Kumbhars utilize shared courtyard spaces, 120 working kilns, and streets as an extension of their homes to socialize and work. They maintain strong ties with their families back at their ancestral villages, collaborating to improve the design of the kiln or import clay from there. The Recycling industry at the 13th compound is one of the largest industries in Dharavi and recycles about 80% of Mumbai’s plastic waste in about 15,000 single-room factories. This recycled plastic is sold to local manufacturing units that make products such as bottle caps, umbrella handles, and children’s toys. One recycling unit recycles, on average, four tons of plastic waste a day. Apart from the plastic recycling units, Dharavi consists of glass, metal, paper and cardboard, tetra pack, and e-waste recycling units dedicated to recycling and sorting Mumbai’s waste employing 250,000 people.

The garment industry in Bareilly compound consists of about 3,000 small-scale workshops each carrying out production, trade, and sales to local shops in Mumbai and also export to international markets to big-box retailers such as Walmart and Kmart. The Leather Industry along the 90-feet road were one of the first to be established in Dharavi when Muslim tanners migrated from Tamil Nadu during the 19th century. It houses more than 5,000 workshops that support manufacturing, polishing, coloring, and retail with an annual turnover of $500 million that export to local as well as international markets. Construction in Dharavi is an ongoing process with increasing population and growing necessities of the communities that reside there. Koli’s from the fishing industry that settled in Dharavi generations ago changed occupations taking up construction business in demand. They now work as local contractors that build housing or workshop spaces in Dharavi.

The industry structure for these businesses is often vertically disintegrated, for example, in the case of the recycling industry: the different units are highly specialized, and the chain of production is broken up into pieces. The close proximity between the different units allows them to collaborate and contributes to the productivity of the place, as transport costs needed for the production chain are minimized. Similarly, in the pottery industry, where the production happens within one single unit from raw material to finished product, there is still a high concentration of similar manufacturing units in certain spaces. The potters, the tanners, the waste managers, are each located in a different area, and their units all next to each other which allows for a minimization of fixed costs, such as logistics. In the garment industry, contracts with large international brands that export a large amount of its goods, and the different units share the transportation costs with each other. These SMEs benefit from the decentralized production and supply networks building stronger bonds among businesses while completing economic challenges collectively and sustainably. Today, these networks are further strengthened by the widely available mobile phones and other technologies.

Dharavi empowers many women-led businesses that are key to social capital and community growth. Some businesses such as Lijjat Papad is a women’s worker cooperative involved in the manufacturing of papad and other consumer goods. The Lijjat Papad community brings women to the forefront not only by providing employment opportunities but also by making them financially independent so that they can earn their livelihood, support their families and build social and economic resilience. Tiffin Business is also a women-run business in Dharavi that makes a variety of food every single day to deliver to offices all over Mumbai. Zari and Embroidery Handwork business supports many women and housewives to work part-time and earn a living. NGOs and other community organizations in Dharavi work with women with this skillset and pay them to teach other women interested in learning the basics skills of stitching/embroidery. These courses are free for those that support newcomers in Dharavi to learn these skills and later find employment at the local workshops.

Even with the current social, economic, and political circumstances, these marginalized yet resourceful communities play a great role in the city’s social and economic growth. The SME’s of Dharavi not only support many livelihoods but also challenge the large-scale industries replacing human workers in the production process by automation and technology.

Through a series of blogs, we would like to explore how the history, existing urban fabric, professional networks, new technology, and inherent social capital in Dharavi, can be a valuable asset for not only strengthening Dharavi’s small scale businesses and manufacturing but also support migrant communities and the long term socio-economic growth of Mumbai. Though Dharavi is looked down upon as an illegal squatter in Mumbai, we understand the asset of its SME’s and labor and how the potential contribution of a digital platform can foster more growth and global competitiveness of these businesses.

Click here to download the PDF